| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Condition : New

Applicable Industries : Hotels, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop, Food & Beverage Shops

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Marketing Type : Ordinary Product

Warranty of core components : 1 Year

Core Components : PLC

Brand Name : Joyshine

Place of Origin : China

Voltage : 220v/380v/410v and Custom made

Power : 58 kw

Dimension(L*W*H) : 8500*1100*1200mm

Weight : 1000 KG

Warranty : 2 years

Application fields : Vegetable processing plant, Commercial catering, Seasoning plant, Fruit processing plant, Snack food factory, Frozen food Factory

Machinery Function : To make French fries or Potato chips

Raw material : Vegetables, Potato

Output product name : Frozen french fries and Frized potato chips

Key Selling Points : Sustainable

Machinery : fresh french fries production line

Machinery material : Food grade 304 stainless steel

Heating method of frying : Electric/Gas/Diesel

Heating method of Blanching : Electric/Gas/Diesel/Steam

French fries size : 7*7,8*8,10*10 and Custom made

Plant scale : Automatic or Semi-automatic

Final products : French fries or Potato chips

Workflow process : Free design

HS Code : 8438100010

Price : $65,000.00/sets >=1 sets

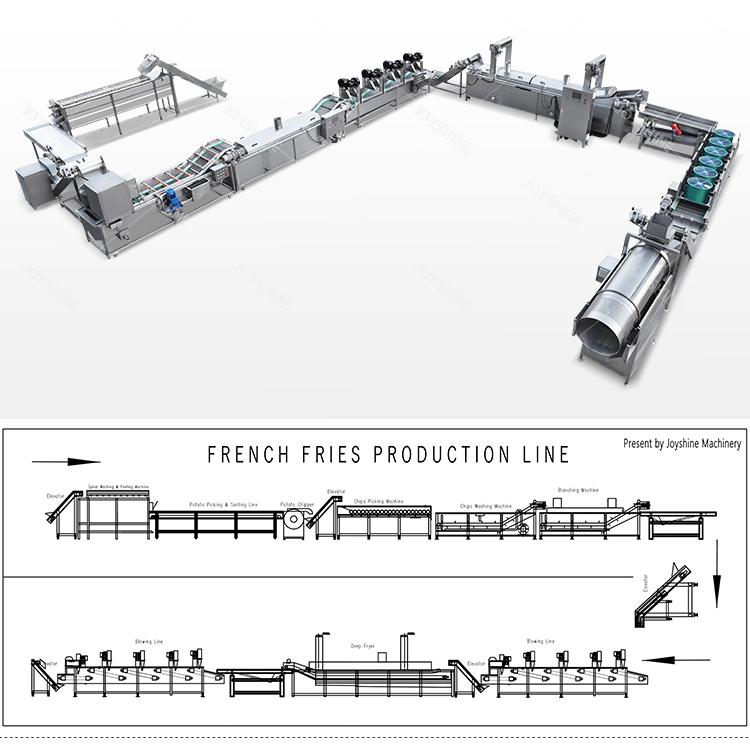

1 | We are a professional manufacture to produce french fries making machines, potato chips making machines, banana chips making machines. | |||

2 | Process capacity including input capacity and output capacity and Process flow can be customized according to your need. | |||

3 | About plant scale, we can do full automatic line (finished capacity 100kg/h to 2000kg/h), it can improve production efficiency and save manpower, it is very suitable for the factory and business with a certain scale and starting business. | |||

4 | Small scale semi-automatic production line(finished capacity 30kg/h to 300kg/h) and its scale is not so big like full automatic line and ask less manpower, its cost is lower than full automatic line, its production method is very flexible, and suitable for a small-scale business or a company that has just begun to enter the industry. | |||

5 | All equipment in the production line is made of 304 stainless steel. | |||

6 | Heating method: Electric heating, Gas heating or Electricity heating and gas heating both in one. | |||

7 | The size of French fries and the thickness of potato chips are adjusted. | |||

8 | We can design floor plan of complete line you need epending on your area' s size. |

No. | Machinery | Feature |

1 | Elevator | It is used to lift fresh potatoes into next step screw washing and peeling machine automatically. |

2 | Screw potato washing and peeling machine | It is used to peel potatoes completely with hard brush and emery brush, uneven and corrugated brushes can peel potatoes completely. |

3 | Inspecting table | It is used to pick out unqualified potatoes such as bad parts and potato eyes manually, this machine can be equipped with Waste bins and return unpeeled potatoes into previous peeling machine. |

4 | Potato cutter | It is used to cut potato strips, strips size can be customized, |

4 | Potato slicer | It is used to cut potato chips, chips thickness can be adjusted. |

5 | Elevator with water bucket | It is used to preclean and lift potato strips into next step Rinsing machine. |

6 | Rinsing machine | It is used to wash potato starch and protect potato from oxidation to keep strips and chips' color. |

7 | Blanching machine | ---It is used to deactivate the activity of the oxidase, take off the starch to keep french fries’s soft taste. ---Heating source can use Gas heating, Electricity heating or Diesel heating any one. ---Blanching time and Blanching temperature can be adjusted. |

8 | Vibration de-water machine | It is used to remove extra water, the bottom with water tray. This machine also has many small holes to leak out waste parts and unqualified parts of strips. |

9 | Air-cooling machine | It is used to do secondary water removal. |

10 | Elevator | It is used to lift potato strips into next step Continuous frying machine. |

11 | Continuous frying machine | ---It is used to fry potato strips into fries in short time. ---Heating source can use Gas heating, Electricity heating or Diesel heating any one. ---Frying time and Frying temperature can be adjusted. |

12 | Vibrating de-oil machine | It is used to remove extra oil and leak out unqualified french fries. |

13 | Air-cooling machine | It is used to do secondary oil removal and cool down the temperature after frying. |

14 | Elevator | It is used to convey fries into freezer from air-cooling machine. |

15 | Fluidized belt freezer | It is used to quick freezing the french fries in short time, fries center temperature at -18 ℃, Can the maximum keep the original flavor and french fries quality. |

16 | Automatic weighing and packaging machine | It is used pack frozen french fries automatically. |

What's the heating method: | Usually it can be electricity heating or gas heating. | ||||||

Material: | All machines adopt food grade 304 stainless steel. | ||||||

Date of delivery: | About 15-25 working days after receiving deposit. | ||||||

Voltage: | Customize according to the needs of different countries. | ||||||

Payment Tems: | T/T、Alibaba Trade assurance、L/C、WU、PayPal、Alipay、WeChatPay. | ||||||

Packing: | Exporting standard wooden case or full container. | ||||||

Transportation: | Shipping by express, air, railway and sea. | ||||||

Warranty: | 2 years | ||||||

OEM: | Customization of nameplate, material, slicing/cutting size, motor brand, packaging, etc. | ||||||

|

|

7*7 French Fries Production Line with Top Selling Fried Potato Fingers Making Machine Images |